The pieces are first roughly shaped from equal lumps of clay. After drying overnight, each one is individually hand-carved to reveal its unique, final form.

The carving process takes up to 20 minutes for each piece. That is why there are no two identical pieces and no two identical Chess Sets.

The Chess Set was born as a gift for my father and brother who enjoy playing the game together.

The shape of the pieces came to me naturally, through playing and handling the clay, the organic, spiralling shape was born.

After the hand carving, the pieces are left to dry over a period of days before they’re submitted to their first firing. After the first firing, they’re hand-dipped in glaze one by one and subsequently refired.

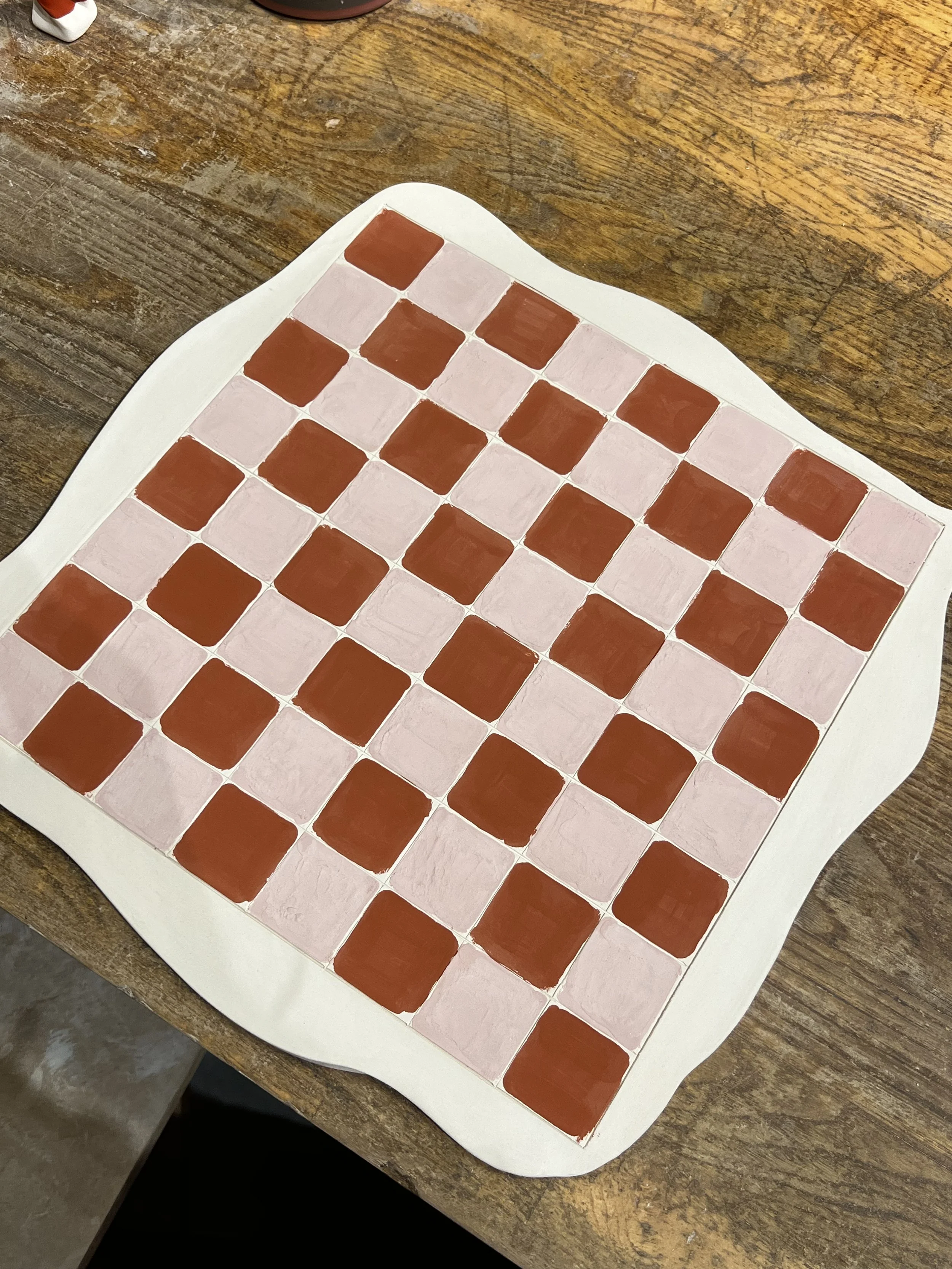

After the drying is complete, the board is fired, then carefully hand glazed with a brush, then fired again.

The board is made from a slab of clay, rolled out by hand, of about 28cmx28cm.

During the drying process, slabs of clay are prone to bending and deforming.

The Chess board must dry for at least 3 weeks in between slabs of wood in order to retain a flat, smooth surface.